How is BIM used in Construction? The Ultimate Guide for Builders & Contractors

This article is a practical guide for contractors to understand how BIM is used in a project, and their role in the development of the BIM model as the project evolves.

Introduction

Building Information Modeling, commonly referred to as BIM, is transforming the architecture, engineering, and construction (AEC) industries. In advanced economies like Singapore, BIM is expected to become a crucial component of the regulatory submission process. Beyond its role in regulatory approvals, BIM fosters collaboration across the built-environment supply chain and has become an integral part of modern construction projects. This article delves into the fundamentals of BIM, explores its benefits, and helps builders understand its impact on the AEC sector.

What is BIM?

Building Information Modeling (BIM) is a digital representation of the physical and functional characteristics of a facility. It goes beyond traditional 2D drawings by incorporating 3D modeling, making it a comprehensive tool for planning, designing, constructing, and managing buildings and infrastructure.

The Types of BIM Software in Construction

1. BIM in the Design Phase

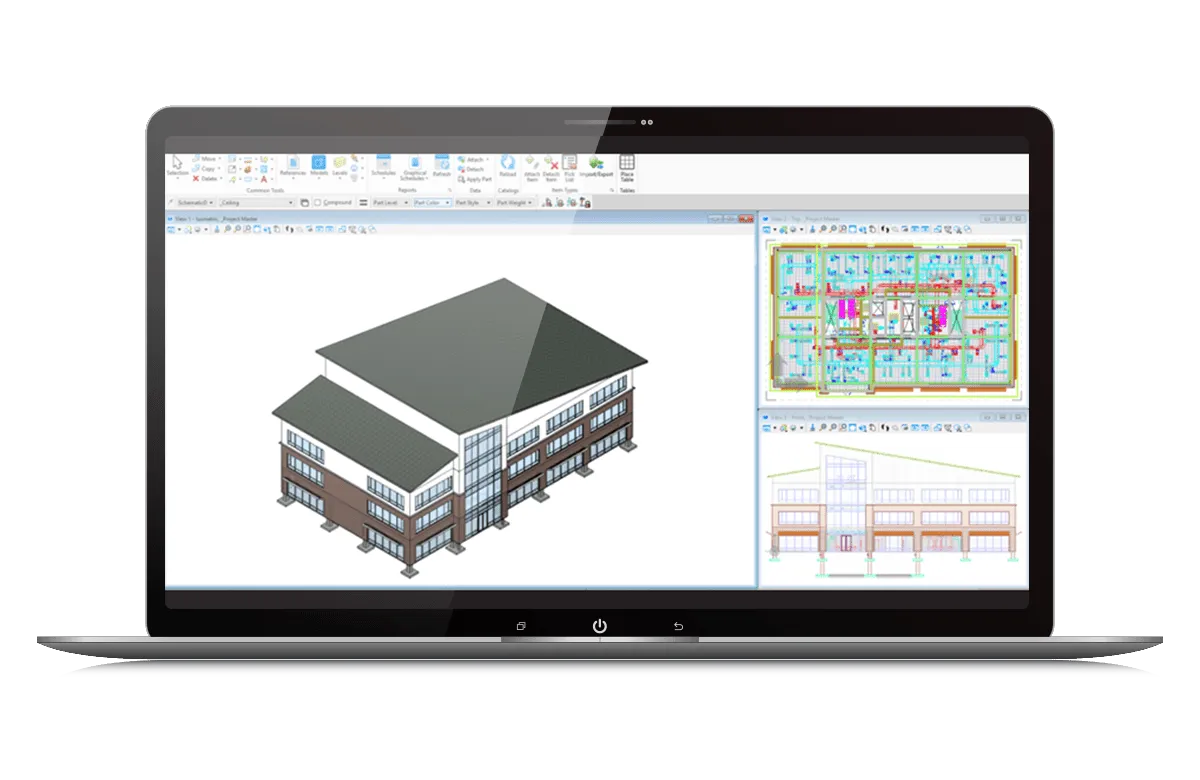

3D BIM Modeling

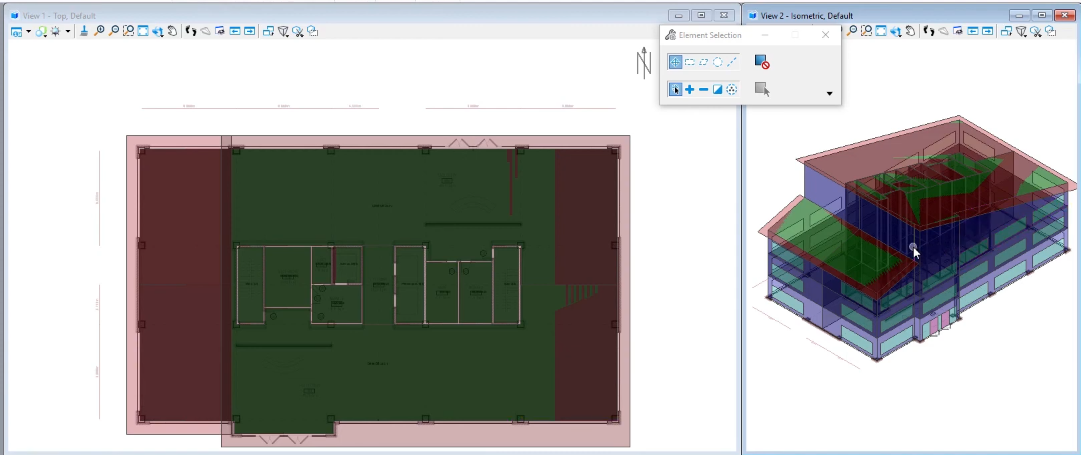

Architects and designers use BIM to create highly detailed 3D models that incorporate architectural, structural, and MEP (Mechanical, Electrical, and Plumbing) elements. These models provide a comprehensive representation of the building, including geometry, spatial relationships, geographic information, and properties of building components.

In most cases, an architect develops the architectural renderings and distributes the design models down the supply chain. Engineering consultants may provide critical analysis of the asset's buildability, particularly regarding its structural integrity on-site. Specialist contractors further enhance the 3D BIM by incorporating building subsystems such as lighting, ACMV, fire protection, and MEP systems. During virtual ICE sessions, BIM models can be used to identify potential clashes that may occur on-site between various building subsystems.

Design Simulations

BIM enables a variety of simulations that can predict a building’s performance before construction begins. These include energy simulations to optimize HVAC systems, lighting simulations to ensure adequate daylighting, and acoustic simulations to enhance sound quality within the building.

These models do not require a very high level of detail in the BIM. Simple geometric representations of structural walls and MEP elements may be sufficient for architects and consultants to simulate the impact of various design changes on the building.

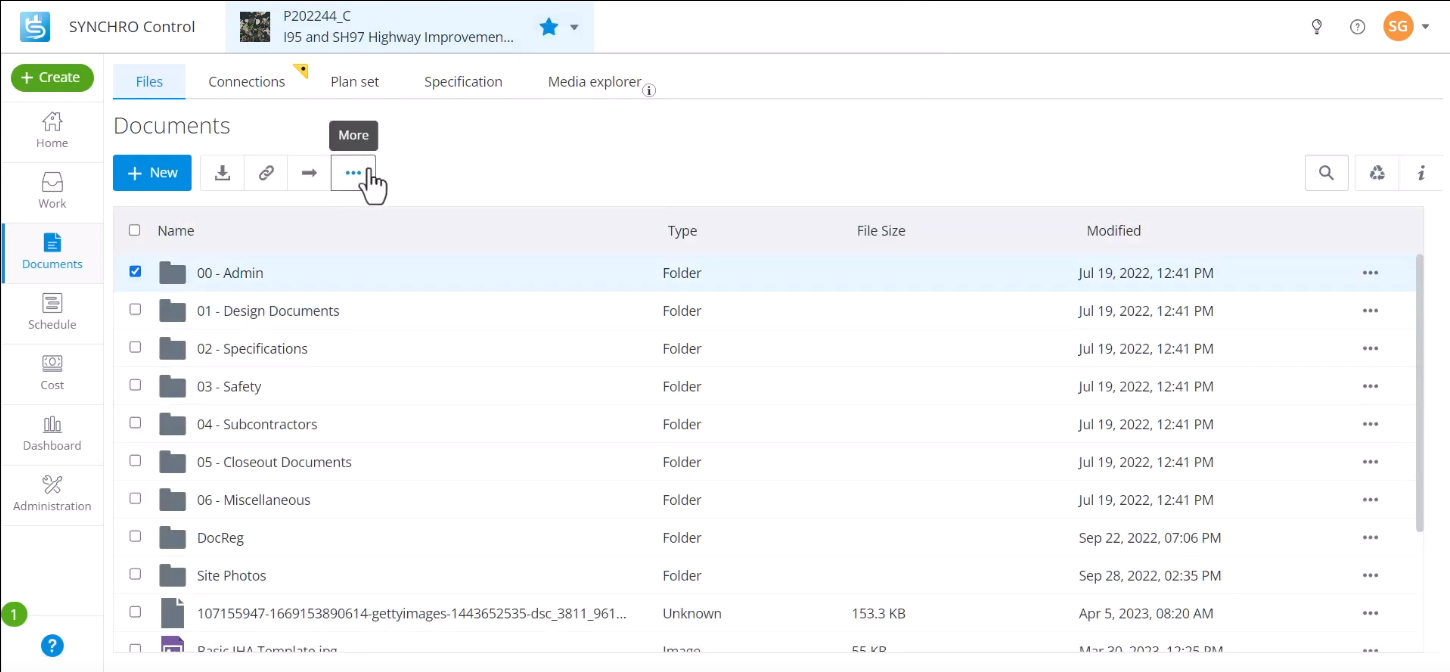

Collaboration & Documentation

BIM automates the generation of construction documents, ensuring consistency and accuracy. These documents include plans, sections, elevations, and details that are directly linked to the 3D model, allowing any changes in the model to be automatically reflected in the documentation. Examples of cloud-based BIM collaboration software include BIM Collaborate Pro (Autodesk), ProjectWise (Bentley Systems), and BIMCloud (Graphisoft).

These platforms offer version control, keeping project stakeholders up to date on any changes to design files and allowing for integration with contract management tools to manage potential contract modifications. When modeled appropriately, detailed 2D construction documentation can be extracted from BIM models for use in the field. These detailed drawings are essential for builders and trade contractors, as they provide precise information necessary for fabricating and assembling building components on-site.

Visualization Tools

BIM software often includes advanced visualization tools that enable architects and designers to create realistic renderings and walkthroughs. These visualizations help in presenting the design to clients and stakeholders, facilitating better understanding and communication of design intent.

Prior to the Construction Phase, BIM visualization tools are also used to conduct Virtual ICE Meetings to minimize the potential for clashes onsite and ensure everyone is aligned to the construction schedule.

2. BIM Use in the Construction Phase

Site Preparation & Analysis

By combining satellite data with drone-captured imagery, a comprehensive topographical context of the construction site can be created. This allows project teams to conduct virtual site analysis, optimize the positioning of structures, and plan for earthworks such as excavation, grading, and drainage. Additionally, BIM facilitates the visualization of site logistics, including the placement of temporary facilities, access routes, and storage areas, ensuring that the site is prepared efficiently and safely for the subsequent phases of construction.

Construction Sequencing

Contractors use BIM to develop construction sequences, often referred to as 4D BIM. Traditionally, complex project schedules are created using tools like Oracle Primavera P6, Microsoft Project, and even Excel. By linking the 3D model with the construction schedule, project teams can visualize the construction process over time. This capability helps identify potential issues during the virtual planning phase, reducing the risk of abortive work on-site.

Site Logistics

BIM aids in planning site logistics, including the placement of cranes, material storage areas, and temporary structures. This spatial planning ensures the efficient use of space and resources on the construction site, thereby improving safety and productivity. Additionally, BIM supports resource planning by providing detailed information on the materials, labor, and equipment required for each phase of construction. This information helps contractors procure the right quantities of materials at the right time and ensures that the necessary workforce and machinery are available when needed.

Progress Tracking

By utilizing reality capture techniques, such as laser scanning or photogrammetry, the current state of the project site can be documented and compared with the original BIM design models. This comparison allows project teams to accurately determine the percentage of completion and identify any deviations from the planned design. Furthermore, BIM collaboration tools enable team members to flag issues on the as-built structures directly within the model. These flagged issues can then be tracked and managed to ensure timely resolution, helping to maintain the project schedule and quality standards.

3. BIM Digital Twins for Operations & Facility Management

Maintenance and Operations

BIM extends beyond construction to support facility management. The BIM model serves as a digital twin of the building, containing detailed information about building components and systems. Facility managers use this data for routine maintenance, repairs, and renovations, ensuring that the building operates efficiently over its lifecycle.

Asset Management

BIM helps in tracking the location, condition, and maintenance history of building assets such as HVAC systems, lighting fixtures, and plumbing. This information supports efficient asset management, reducing downtime and extending the lifespan of building components.

Space Management

BIM provides detailed information on the spatial layout of the building, including room dimensions, occupancy, and usage patterns. Facility managers use this information to optimize space utilization, plan for future renovations, and manage occupancy levels.

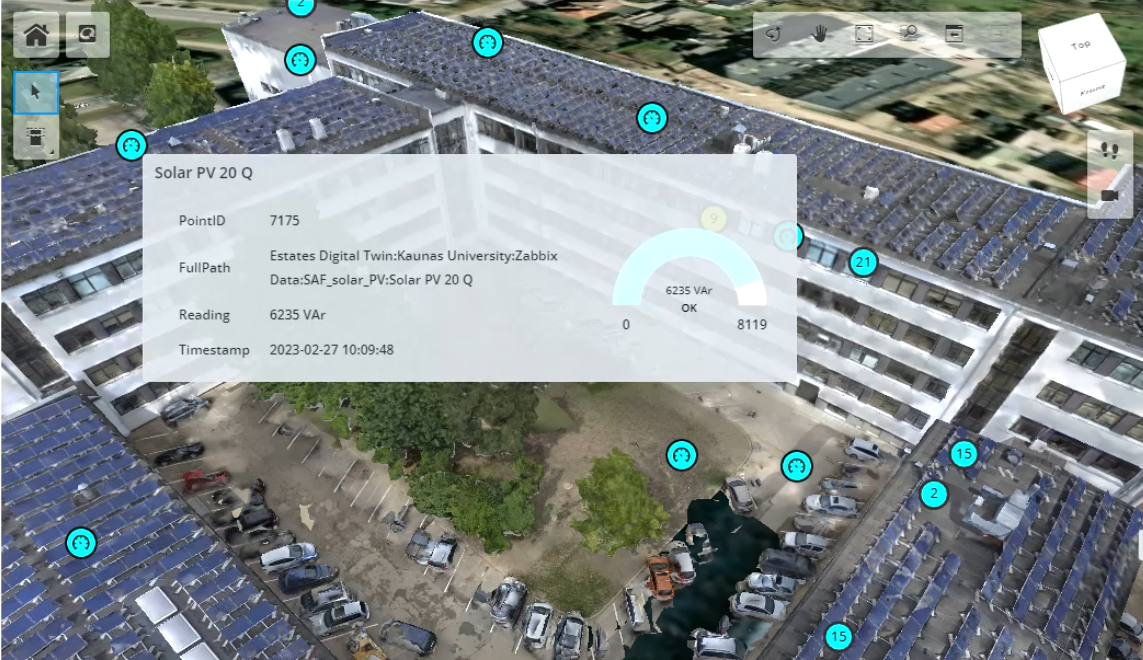

Operational Data Integration

BIM models can be integrated with data from building sensors and IoT devices to create a functional digital twin. This integration allows facility managers to monitor building performance in real-time, including energy consumption, indoor air quality, and occupant comfort. By analyzing this data, managers can make informed decisions to improve building operations and reduce costs.

The Future of BIM

BIM is continuously evolving, with advancements in technology driving new capabilities. The integration of artificial intelligence (AI), the Internet of Things (IoT), and augmented reality (AR) promises to further enhance the potential of BIM. These innovations will lead to smarter buildings and more sustainable construction processes.

Building Information Modeling (BIM) is revolutionizing the AEC industry by improving collaboration, increasing efficiency, and enhancing project outcomes. As the industry continues to embrace digital transformation, BIM will remain a critical tool for achieving excellence in building design, construction, and management.