Automated BIM Quality Checks for Strict Project Compliance

The construction industry is steadily undergoing a digital transformation, with a growing demand for better model coordination among project stakeholders. Building Information Modeling (BIM) is at the heart of this transformation, not only eliminating ambiguities in project information but also enhancing value by embedding comprehensive data about building assets.

As BIM models become more complex, effective management and verification are crucial to ensure accuracy and compliance with standards. Rule-based model checking provides a structured, repeatable, and automated approach to validating BIM models during the quality assurance process.

Types of Model Checks

Model checking involves validating different types of data within BIM models, each serving a specific purpose.

These checks fall into three broad categories:

- Geometry Checks (The Visual Layer)

- Parametric Checks (The Embedded Data Layer)

- Project Standards Checks (Project-Specific Information)

Understanding these categories helps determine the appropriate type of validation required.

1. Geometry Checks

Geometry checks focus on the 3D representation of building assets, examining aspects like shape, form, distances, and element placement.

Common geometry checks include:

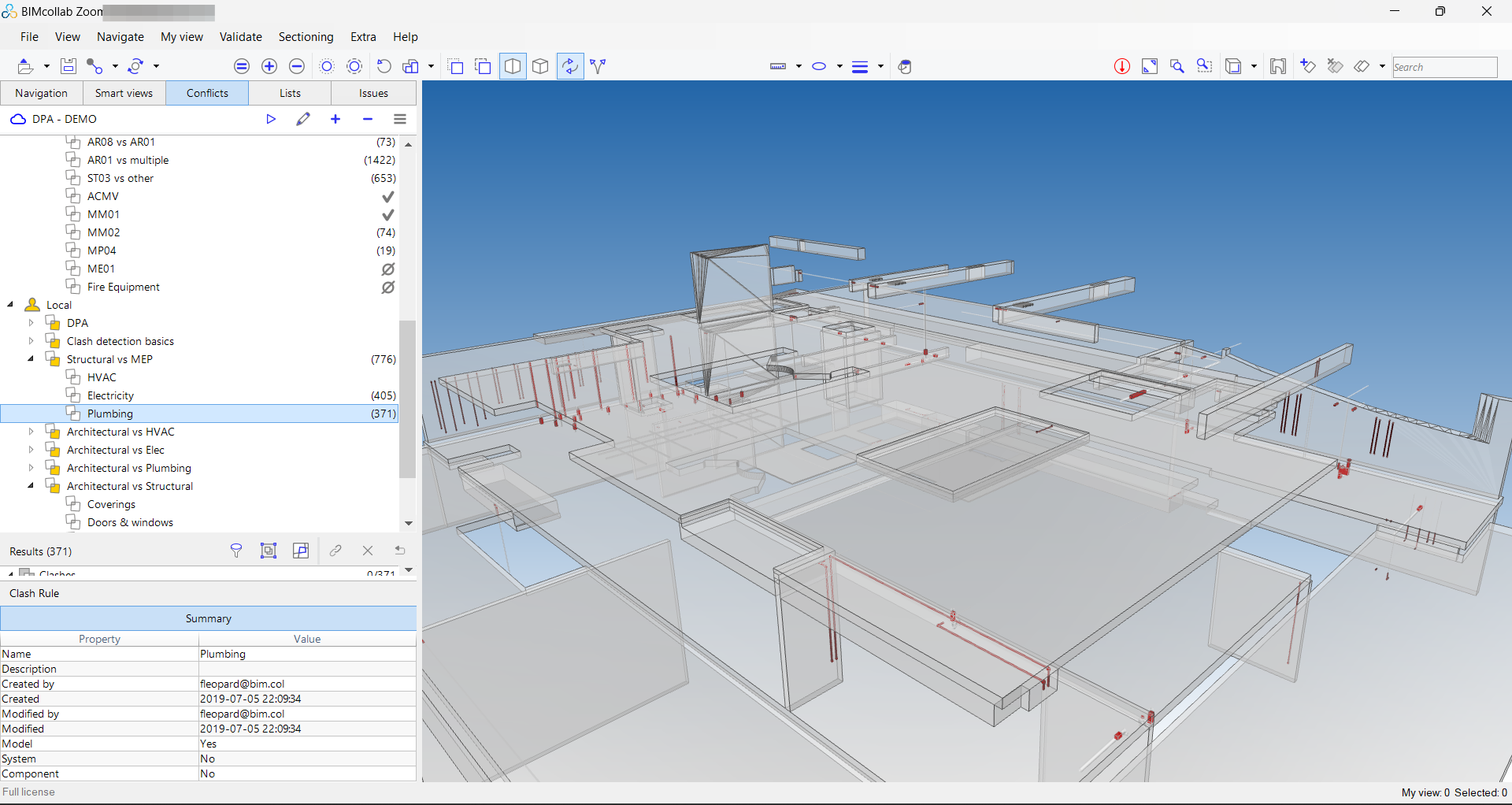

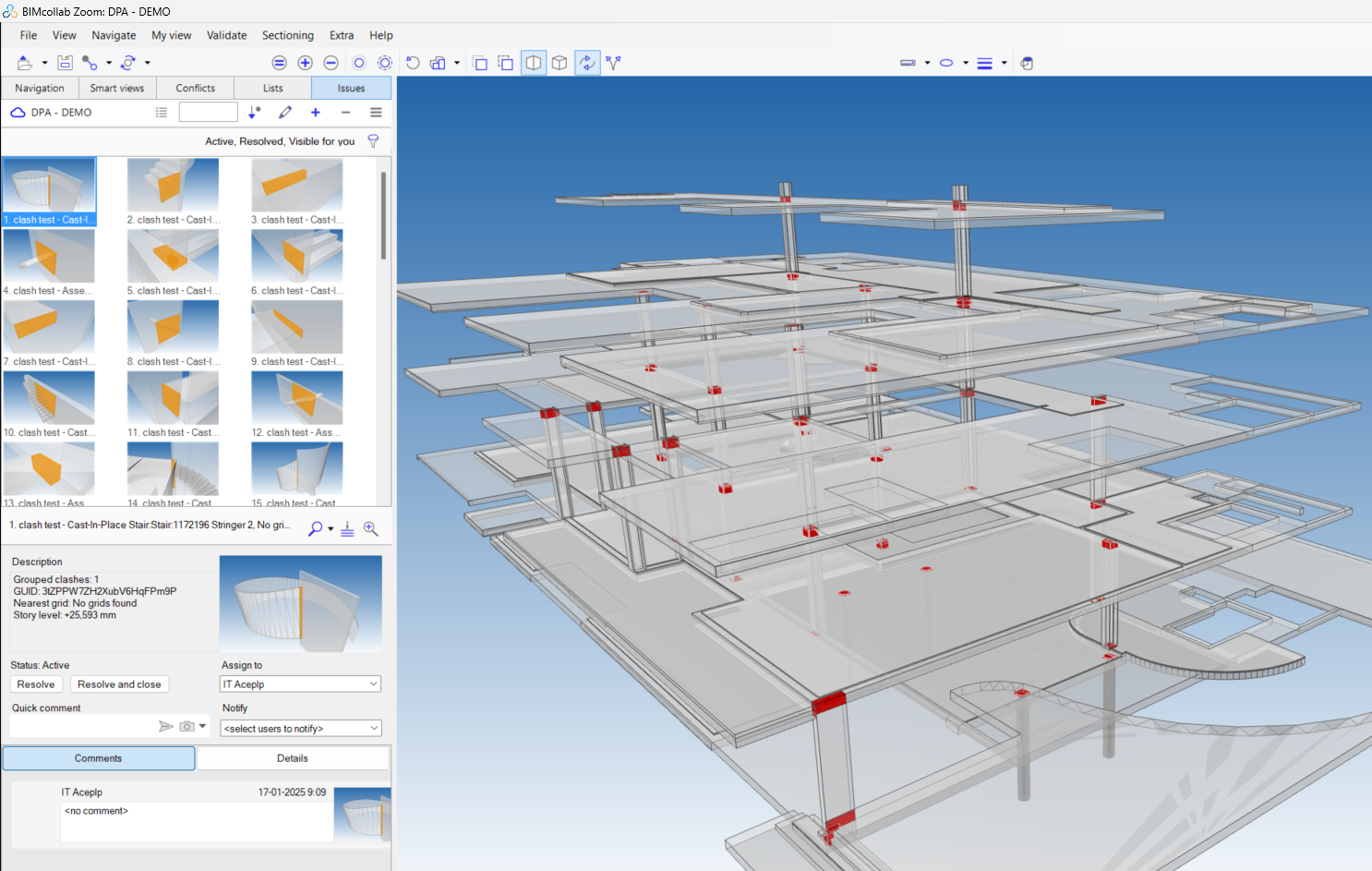

- Clash Detection – Identifies instances where different building elements intersect or are too close within a specified margin.

- Distance Validation – Ensures elements meet minimum spacing requirements.

- Duplicate Detection – Flags duplicate elements occupying the same location.

- Presence/Absence Checks – Verifies that essential building components are included in the model.

2. Non-Graphical Data Checks

These checks focus on embedded parameters and metadata within the BIM model. A key example is Singapore’s CORENETX BIM submission system, where BIM models must include IFC-SG parameters for regulatory compliance.

Typical data checks include:

- Parameter Presence – Ensures required parameters exist within the model.

- Empty Values Check – Detects missing or unfilled parameters.

- Value Accuracy – Validates parameter values against predefined rules, including:

- Typos and Case Sensitivity – Identifies incorrect capitalization, forbidden symbols, or formatting errors.

- Standard Compliance – Ensures adherence to industry-specific conventions, such as COBie naming standards.

3. Project Requirements Checks

These checks verify that building assets align with project-specific, national, governmental, client, or company standards.

Examples include:

Design Criteria Validation

- Compliance with program requirements.

- Minimum door and window sizes.

- Consistency of floor areas with designated room types.

Regulatory and Building Code Compliance

- Minimum ceiling heights for specific spaces.

- Required number of toilets and bathrooms.

- Compliance with wheelchair accessibility dimensions.

- Minimum door widths and heights.

- Proper sizing of emergency escape routes.

Certain buildings in Singapore must meet accessibility design requirements. Walkways must have a minimum width to ensure compliance. In complex projects, these requirements can be automatically validated and codified as rule-based model checks, ensuring that designs adhere to regulatory standards without manual oversight.

Why Use Rule-Based Model Checking?

In our experience, for large projects with multiple models and extensive data requirements, manual quality checks are impractical. Rule-based model checking automates quality control, reducing the need for intensive human oversight.

Real-World Examples

Rules define specific conditions that BIM models must meet. Below are practical applications of rule-based model checking:

Example 1: Distance Between Structural Columns/Beams and HVAC Components

Requirement:

All structural columns and beams must maintain a minimum 50mm clearance from HVAC systems.

Implementation:

- Define Minimum Distance – Set the required 50mm spacing.

- Group Elements –

- First Group: Structural columns and beams.

- Second Group: HVAC system components.

After running the check, the program identifies HVAC ducts that are too close to structural columns, enabling corrective action before construction.

Example 2: Standardized Floor Naming Convention

Requirement:

All floor levels must follow a specific naming format (e.g., "01 – Floor", "02 – Floor", "Roof", "Parapet").

Implementation:

- Parameter Definition – Apply the rule to the "Floor" parameter.

- Allowed Values – Specify acceptable names.

- Case Sensitivity – Enable case-sensitive validation to detect capitalization errors.

The program flags elements associated with incorrect level names, ensuring standardization across the project.

Example 3: Presence of "LoadBearing" Parameter

Requirement:

All structural elements must include the "LoadBearing" parameter, with valid values such as "Yes" or "No".

Implementation:

- Element Selection –

- First Group: Structural elements (e.g., beams, columns, load-bearing walls).

- Parameter Check – Ensures the "LoadBearing" parameter exists and is correctly populated.

If any structural element lacks the required parameter or contains incorrect values, the program flags it for correction.

Key Benefits of Rule-Based Checks

1. Automation and Time Efficiency

Manual checks are time-consuming and prone to human error. Automated rule-based validation streamlines the quality control process, significantly reducing time and effort. Integrating model checks into the BIM delivery workflow ensures consistency and improves overall project efficiency.

2. Consistency and Accuracy

Standardized rules ensure that every validation follows the same criteria, eliminating inconsistencies caused by subjective interpretations. This approach also supports compliance with complex information management standards, such as ISO 19650, enhancing project-wide data integrity.

3. Early Error Detection

Detecting issues early in the design phase minimizes costly rework later in the project lifecycle. Addressing problems virtually is always preferable to discovering them on-site—where delays, wasted materials, and increased costs can significantly impact the project.

Top Tools for BIM Quality Control

Several software solutions support automated BIM model validation, including:

- Solibri Office – A Java-based model checker compatible with IFC files, widely used for rule-based validation.

- Navisworks – Primarily used for clash detection, but also supports custom rule-based checks for native Revit files.

- BIMcollab ZOOM – A lightweight model checker designed for issue management and verification.

While these tools often come with pre-configured rulesets, they may not always align with local regulatory requirements. Collaborating with an experienced ruleset configurator can be essential in customizing BIM QA/QC processes to meet specific project and compliance needs.

Conclusion

As BIM adoption accelerates, the need for structured, automated model validation becomes more critical. Rule-based model checking ensures higher-quality BIM models, regulatory compliance, and fewer costly errors, ultimately improving project outcomes.

By integrating rule-based validation, AEC professionals can enhance efficiency, accuracy, and collaboration, driving better results in modern construction projects.